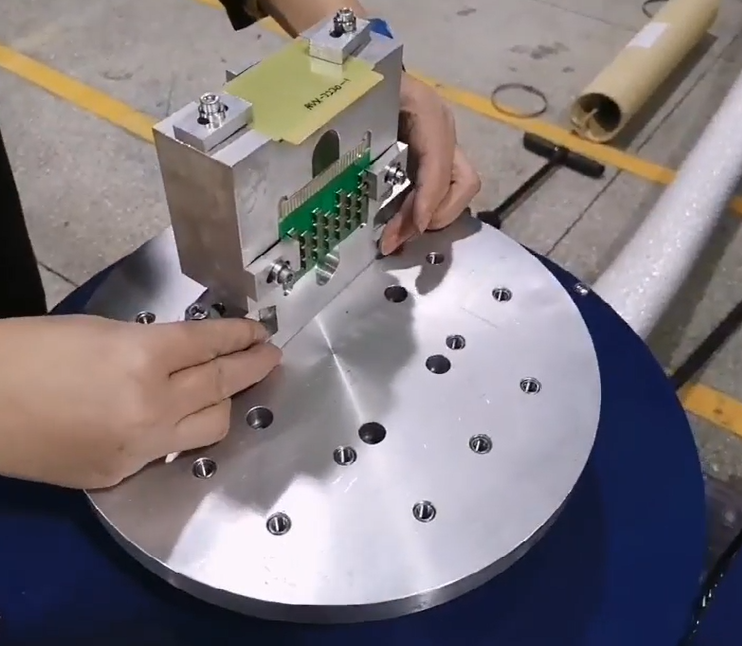

A Printed Circuit Board (PCB) is a vital component in many electronic devices. PCBs are designed to withstand various environmental conditions, including vibration. PCB vibration test benches are used to test the durability and reliability of PCBs in these environments.

During the test, the PCB is subjected to a series of vibration cycles of different frequencies and amplitudes. The vibration is applied in different directions, including vertical, horizontal, and rotational directions, to simulate real-world scenarios. The vibration generator is typically controlled by a computer system that can adjust the amplitude and frequency of the vibration.

Technical Parameters

Model | Rated Sine Force (N) | Rated Random Force (N) | Frequency Range (Hz) | Rated Acceleration (m/s2) | Rated Speed (m/s) | Rated displacement (p-p)mm | Max. Loading (Kg) | moving coil (Kg) | Dimension of Moving coil (mm) |

ES-3 | 3000 | 3000 | 3-3500 | 1000 | 1.6 | 25 | 100 | 3.5 | Φ150 |

ES-3a | 3000 | 3000 | 3-3500 | 400 | 1.6 | 40 | 120 | 9 | Φ230 |

ES-6 | 6000 | 6000 | 3-3500 | 1000 | 1.6 | 25 | 180 | 6.5 | Φ230 |

ES-6a | 6000 | 6000 | 3-3500 | 1000 | 1.6 | 51 | 250 | 12 | Φ230 |

ES-10 | 10000 | 10000 | 3-3000 | 1000 | 1.8 | 51 | 270 | 14 | Φ240 |

ES-20 | 20000 | 20000 | 3-3000 | 1000 | 1.8 | 51 | 300 | 30 | Φ320 |

ES-30 | 30000 | 30000 | 3-2800 | 1000 | 1.8 | 5l | 450 | 40 | Φ450 |

ES-40 | 40000 | 40000 | 3-2800 | 1000 | 1.8 | 51 | 500 | 50 | Φ450 |

ES-50 | 50000 | 50000 | 3-2700 | 1000 | 1.8 | 51 | 750 | 50 | Φ450 |

ES-60 | 60000 | 60000 | 3-2700 | 1000 | 1.8 | 51 | 750 | 60 | Φ450 |

ES-100 | 100000 | 100000 | 3-2500 | 1000 | 1.8 | 51 | 1000 | 90 | Φ450 |

ES-120 | 120000 | 120000 | 3-2200 | 1000 | 1.8 | 51 | 1100 | 90 | Φ500 |

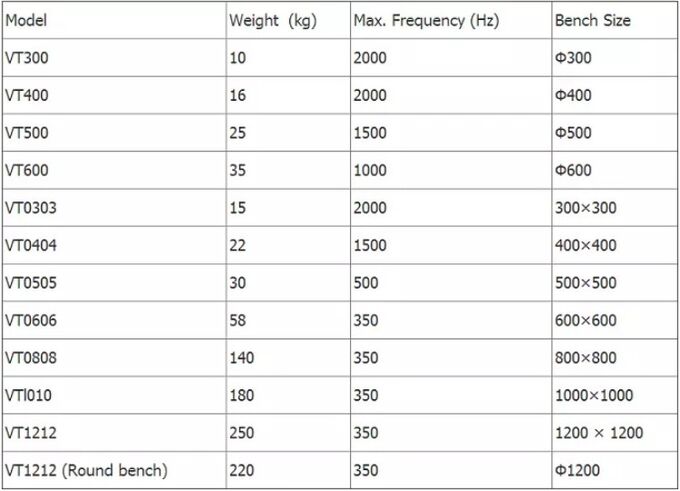

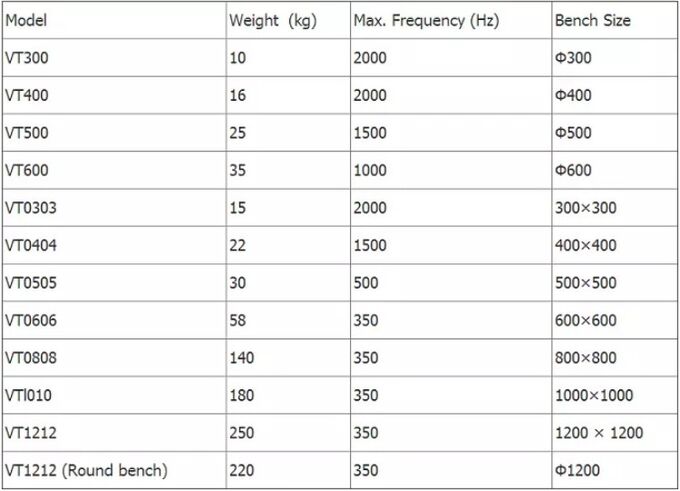

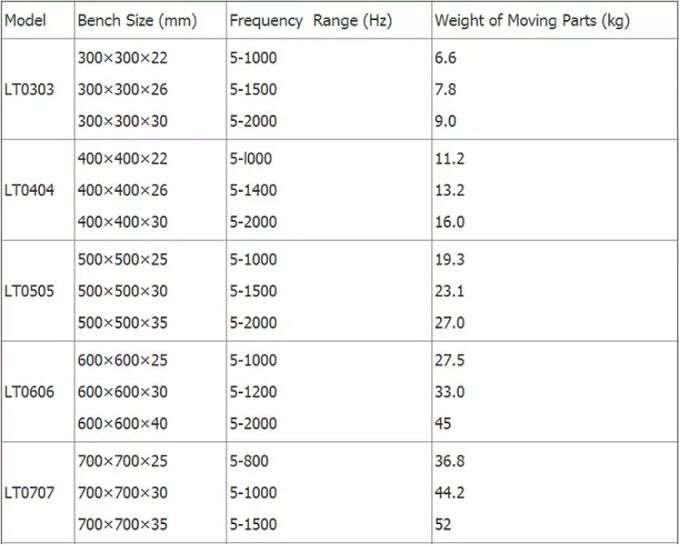

Technical parameters of horizontal expander:

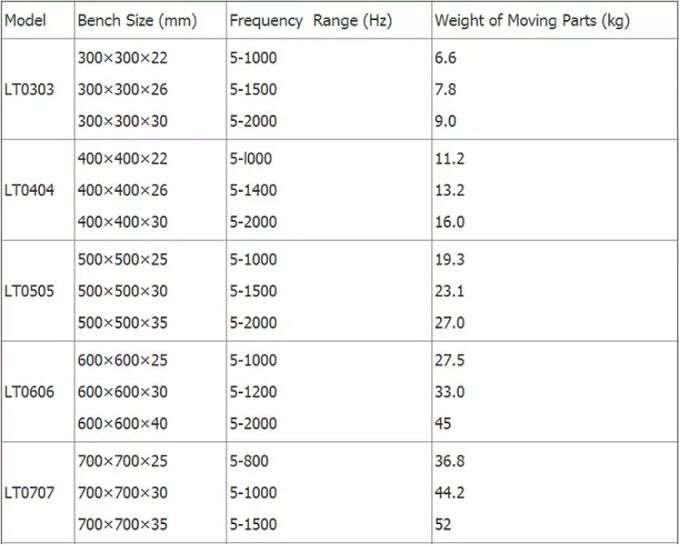

Technical parameters of vertical expander: