UV Preconditioning Chamber, PV modules aging tester

Meet the UV preconditioning test requirements specified in the 4.10 clause of the IEC 61215-2016 standard and the standard MST54 of the IEC 61730-2016 standard. Specially designed UV metal halide lamps are used to test photovoltaic products and materials.

1. The temperature of the lamp could be cooled down in a closed chamber, which is cooled by a water cooling chiller.

2. Module temperature could be controlled by wa ater cooling chiller with cooling air blowing on the module.

3. UV metal halide lamps are used with high value performance, low test cost.

4. The irradiance of each UV lamp can be controlled separately to adjust the irradiance of each lamp.

5. During the test, the UV irradiance data can be tracked. After the irradiation reaches the requirement, the test can be stopped automatically.

6. With the power off memorizing function, which could accumulate the data before powering off.

7. Real-time curves of UVA & UVB radiation, temperature of the module could be shown on the display, and history curves could be accessed.

8. Data of UVA & UVB radiation, temperature of the module could be could be memorized in the hard

disc of the IPC as EXCEL format.

Item | Parameters |

Uniformity of irradiation surface | ≤15% |

Spectral range | 280nm~400nm |

Damp heat test | 85℃/85%R.H |

|

|

UV irradiance(280nm-400nm) | 150~250W/m2 |

UVB ratio | 3%~10% |

UVA Radiometer Range | 0~300W/m2 |

UVA Radiometer accuracy | ±3% |

UVB Radiometer Range | 0~50W/m2 |

UVB Radiometer accuracy | ±3% |

Temperature of the module | 60±5℃ |

Temperature accuracy | ±2℃ |

Temperature repeatability | ±0.5℃ |

Summary and conclusion

One of the significant factor to snail trails is the composition of EVA.

EVA with suitable substance could resist snail trails.

Products of some EVA suppliers have been proved to work well.

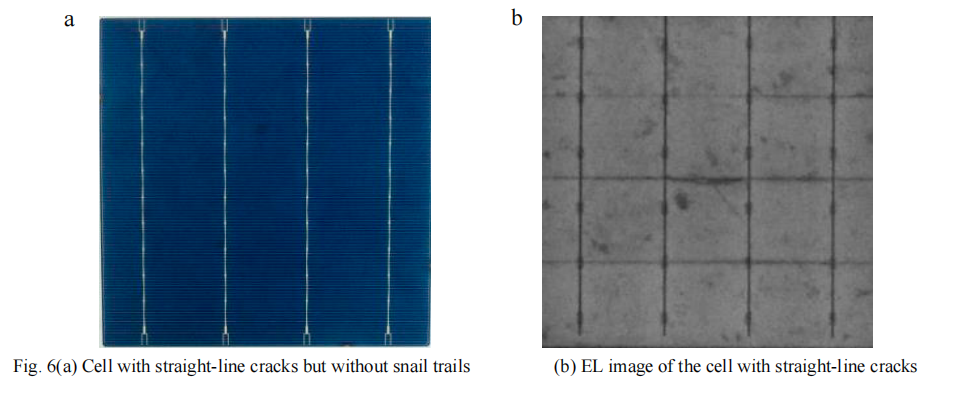

Backsheet is not the key contributor to snail trails. Snail trails will always appear with or without backsheet. Narrow cracks, or microcracks, are also a key factor. They prevent the moisture from evaporating out of the module, hence effectively preventing the humidity inside PV module from dropping. It is easier to create snail trails under such condition. Compared with regular Damp Heat test, UV+DH test condition plus specially designed evaluation samples could generate faster results. It is proven that it will shorten the testing time by 50%. Also, straight line cracks caused by laser cut is effective and helpful for quantitative evaluation of snail trails.With UV+DH test conditions, the probability of snail trail appearance is guaranteed.It can accelerate the process of PV module and EVA R&D. Most white belt zones, which were found along the straight cut lines, converted into snail trails.