Power Supply & Current continuity monitoring system

Additional notes:

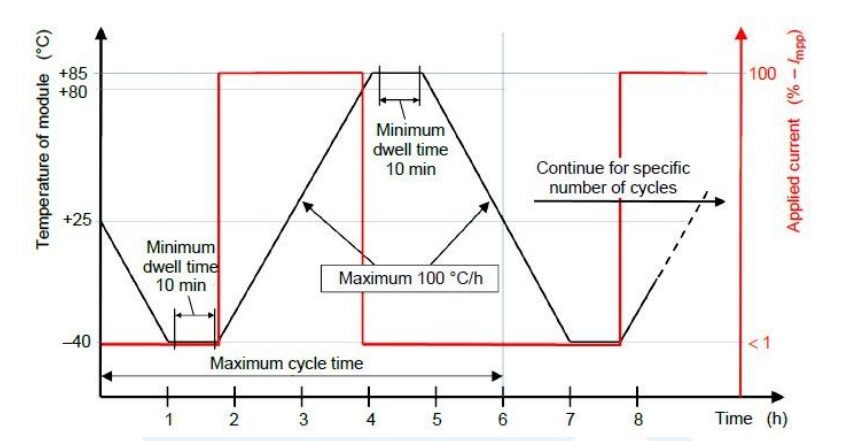

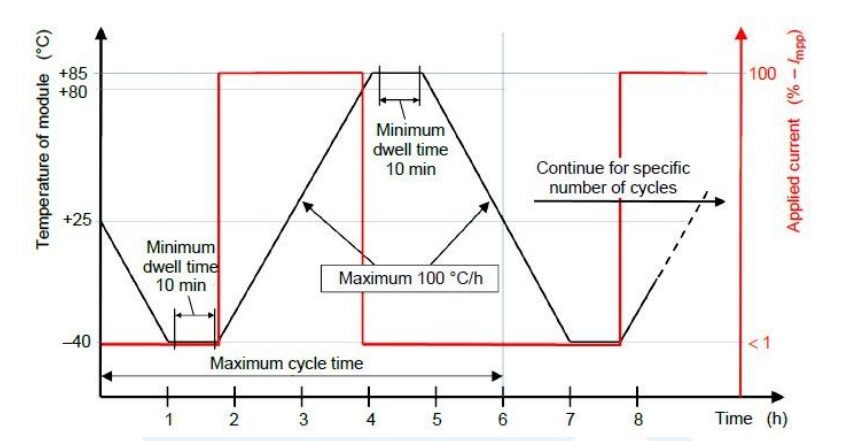

1. For the internal circuit conductivity, 25℃ above the Imp current, through the temperature control current on and off, on and off temperature can be set;

2. The component can pass 1%Imp current, through the temperature control current on and off;

3. In the heating stage between -40 ℃ and 80℃, the component inside the Imp current, in other stages, the component inside the current is not more than 1%Isc;

4. Simultaneously meet IEC61215(2005),IEC61215(2016) and IEC61215(2021) standards;

Functional features

l Adopt special heat dissipation channel to avoid the phenomenon of high temperature caused by long-term high current heating and ensure long-term uninterrupted operation of equipment;

l Stable constant current power supply is adopted to avoid overload power failure caused by unstable internal resistance in the case of alternating high and low temperature;

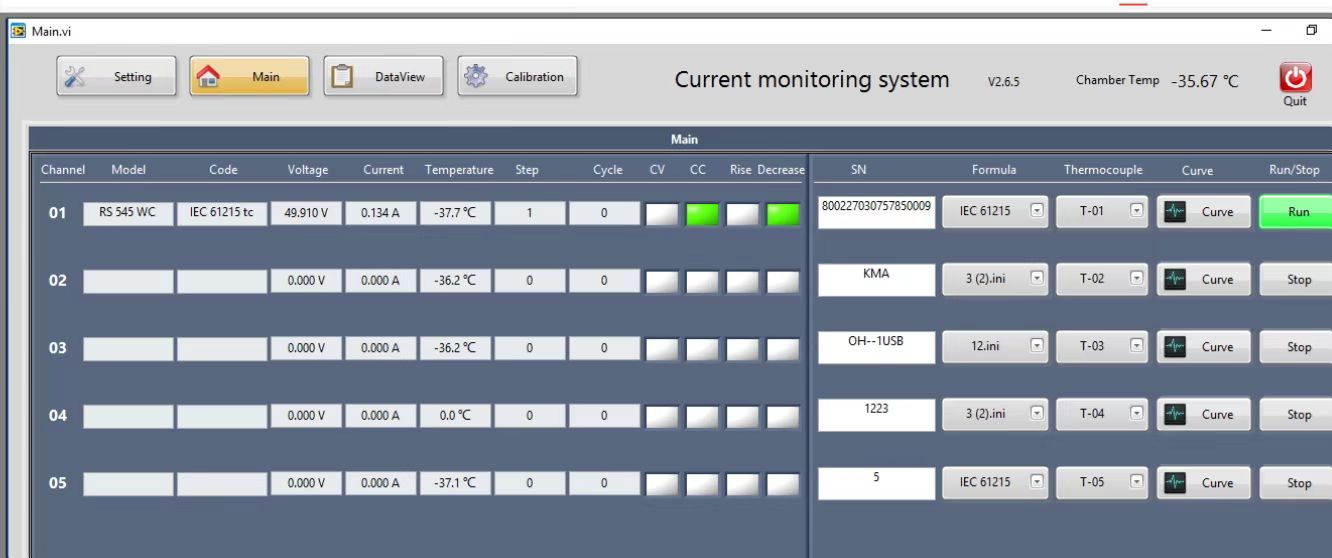

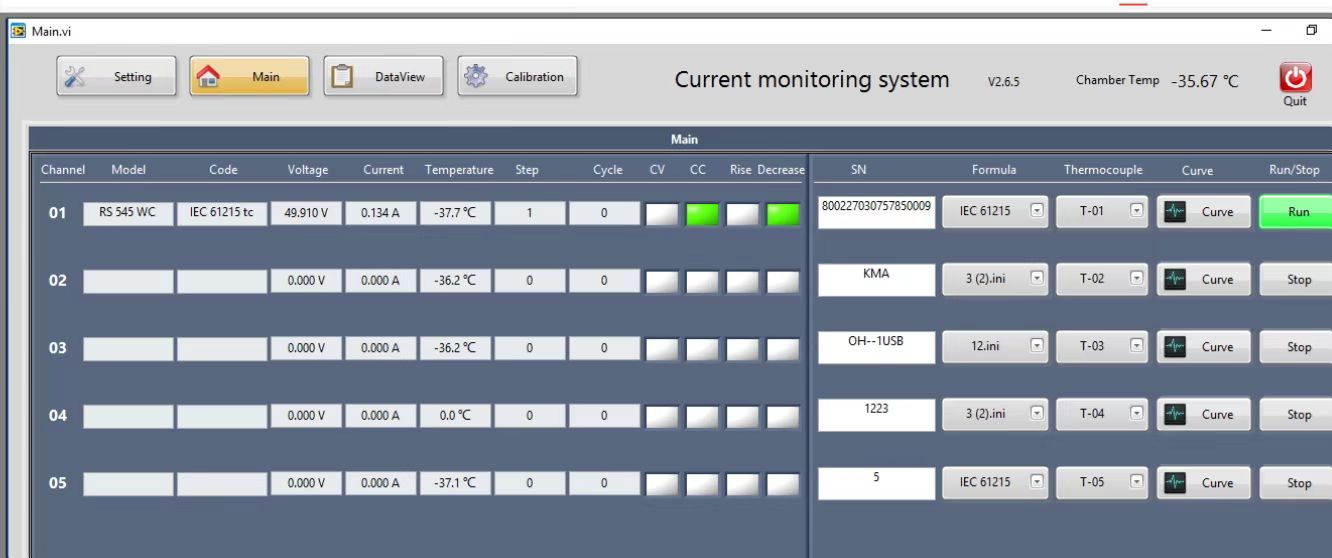

l The single current control function required in the standard is improved, and the multi-channel current recording control function is adopted to realize the independent temperature control function of a single component, to ensure that each component can meet the experimental conditions, while monitoring the temperature performance of each component under the alternating high and low temperature;

l Can communicate with the environment box, monitoring the temperature and humidity data of the environment box;

l Equipped with 5N weight, in the electrification process to apply tension;

l Good man-machine interface, using high quality industrial computer, to ensure long-term stable operation of equipment. It can monitor the specific data of current and temperature, and obtain the current and temperature curves of the whole process, which can be output and printed in EXCEL form.

power supply

l Voltage range: 0-100V;

l Accuracy: 0.2%±40mV;

l source voltage adjustment rate: ≤0.2%;

l Load adjustment rate: stable voltage ≤1%, steady flow ≤2%;

l Working environment: -10 ~ 45℃;

l Current range: 0-30A;

l accuracy: 0.2%±3mA@≥200mA/3mA@≤200mA;

Temperature Sensor

l OMGGA temperature measuring line

l Material: teflon

l Test range: -50 ~ 200℃;

l Accuracy: ±1%

Data acquisition and control

l Support RS485 communication, support J,K,T,E,R,S and B thermocouple input

l 16 bit resolution

l 8 differential input

l T /C software configuration, low voltage and current input

l Isolation voltage: 3000 Vdc

l Support Modbus/RTU control

l DC24V power supply

industrial Computer

l 42U standard chassis;

l 300W power;

l 14S4 baseplate (including 4PCI slot);

l ANOVO 7865L CPU Long card;

l CORE E2180;

l 4G DDR memory;

l 1T hard disk;

l DVD cd-rom drives.

l 19 "LIQUID crystal display