Humidity freeze test chamber IEC61215

Humidity-freeze test

Test is performed according to IEC 61215:2005.

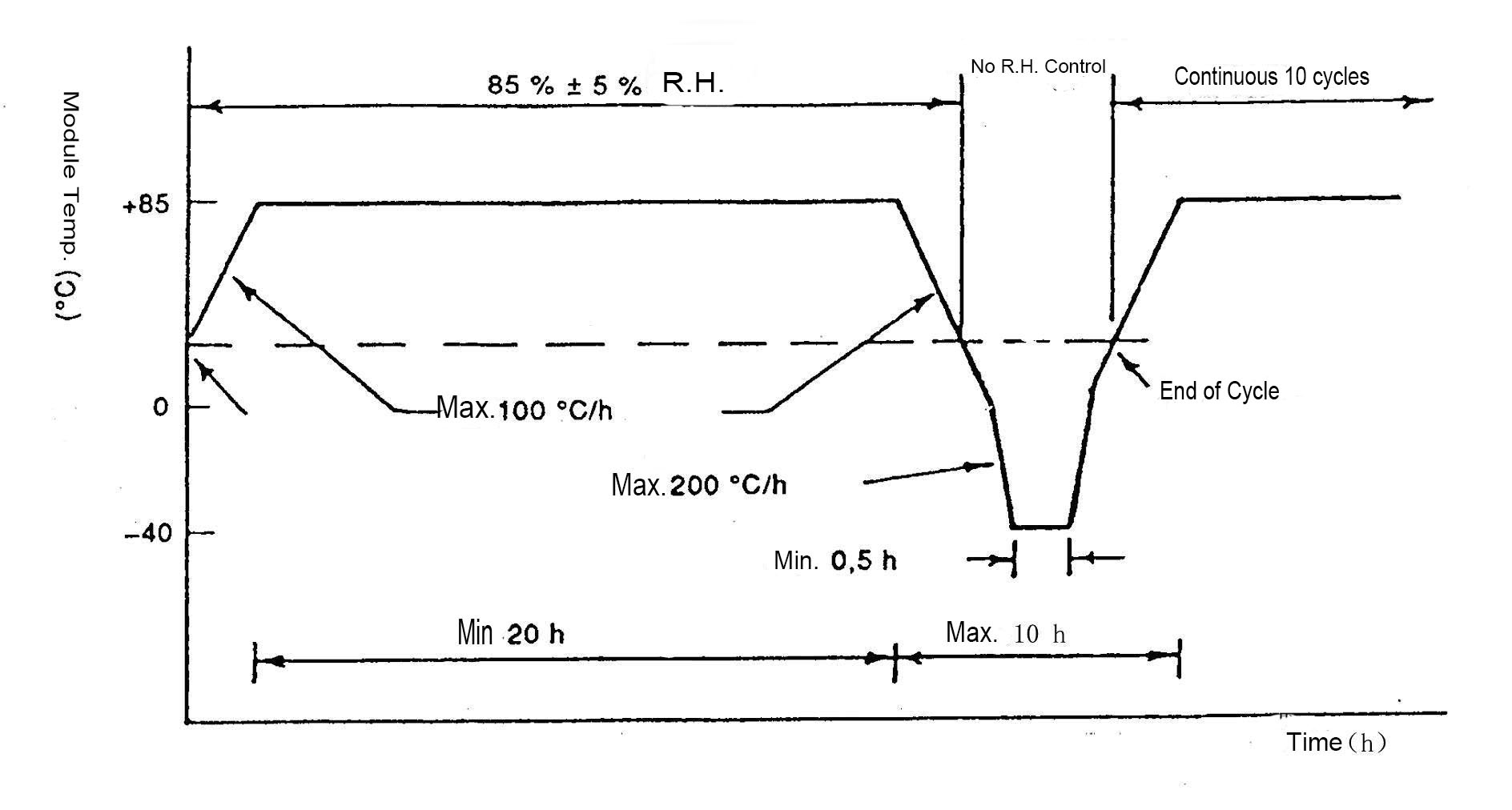

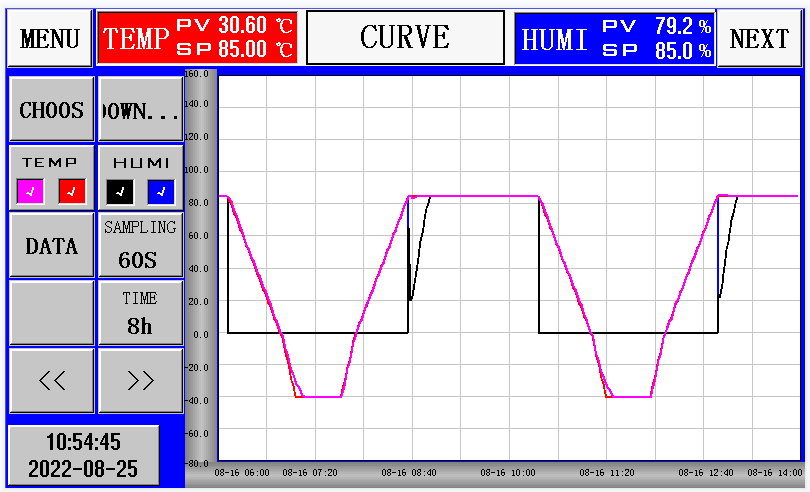

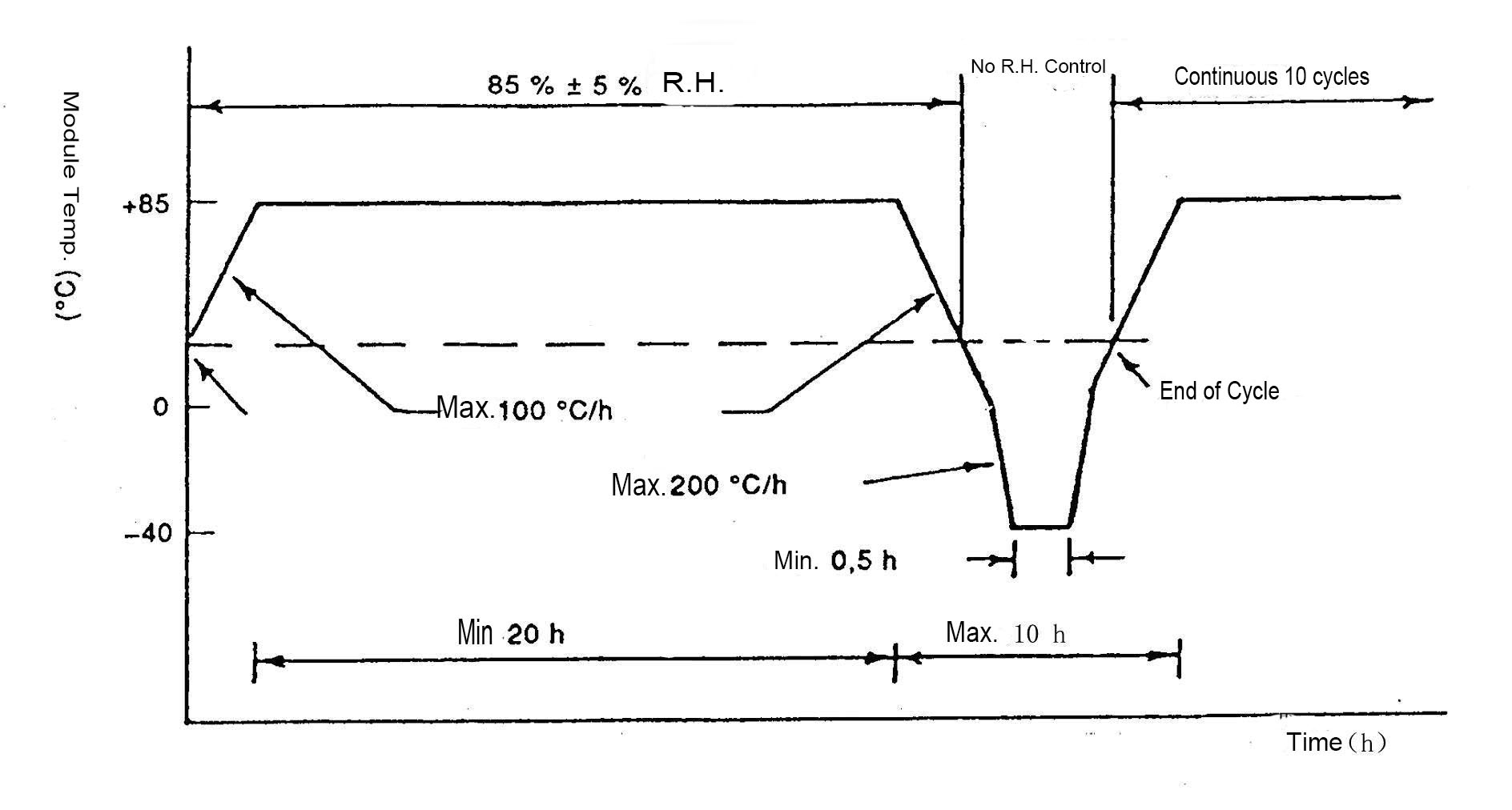

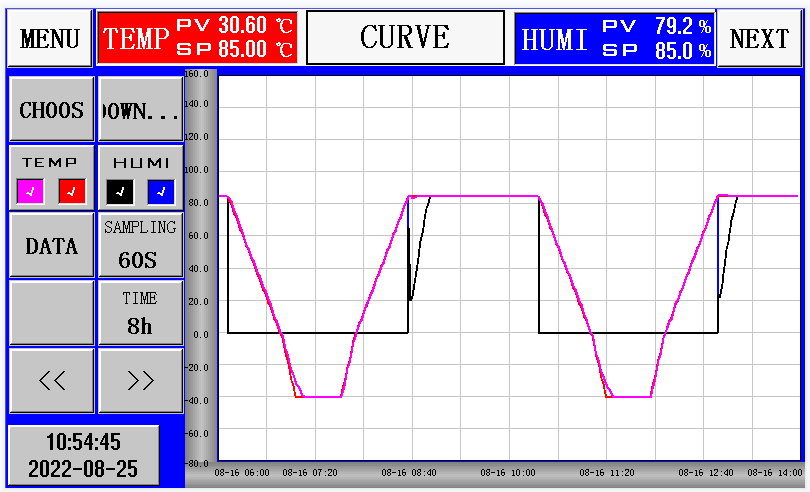

PV modules are subjected to cycling between temperatures of 85°C with relative humidity of 85 % and -40°C. PV modules are subjected to 10 complete cycles in the closed climatic chamber in accordance with the profile in the picture below. The purpose is to determine the ability of the module to withstand against humidity penetration.

Damp/heat ( IEC 61215 MQT 13)

thermal cycling ( IEC 61215 MQT 11)

humidity Freeze test( IEC 61215 MQT 12)

Brief Introduction for PV Modules test standards:

The designed usage time for solar cell module is about 20~30years , and the reliability test is the simulation of the earth's surface photovoltaic modules (crystalline silicon and amorphous silicon thin film, concentrating) design verification, can let the module long-term operating more than 20 years in a general climate , specification requires that solar cells module do test below :

To confirm the solar cell can withstand high temperature and high humidity level with the minus temperature influence, as well as for repeated change caused by the temperature and thermal fatigue failure, in addition to determine solar cells resistant to moisture long-term penetration ability of the test equipment design and ability to meet the relevant standards below:

(IEC61646 , IEC61416 ,IEC61215 , UL1703 , IEC62108 , IEEE1513 ,IEC61730 etc ) .ower :IEC62108 , IEEE1513