Highly Accelerated Stress Test (HAST/PCT) Chamber for Fast Reliability Testing

Control System:

1. Micro-computer saturated steam LED digital display temperature controller, LED digital time controller, and pointer-type pressure display gauge.

2. This system complied with high-pressure accelerated aging reliability test standards such as CNS, ISO, JIS, ASTM, and DIN... BS, IEC, NACE, UL,MIL…

3. Control object: microcomputer +P.I.D. +S.S.R. Automatic calculating saturated steam temperature.

4. Micro-computer control.

5. Temp. Control Accuracy : (+/-)0.5ºC

6. Resolution : 0.1ºC

7. Pressure control accuracy : (+/-)0.2Kg/cm2

Performance:

1. Temp.Range: ( RT+10ºC ) ~ 135ºC Free setting (saturated steam

temperature). 2. Humidity Range: 100%RH (default value of saturated steam humidity )

3. Pressure Range: 0.5Kg/cm2 ~ 3.0Kg/cm2 Absolute pressure; (safe pressure

capacity 3Kg/cm2 = 1environmental pressure + 2Kg/cm2 )

4. Time Range : 0 ~ 999H / M / S ; optional ; free setting

5. Temp. Uniforminity : (+/-)2.0ºC(100ºC)

6. Temp. Rising Time : ( RT+10ºC ) ~ 120ºC About 45 mins

7. Pressure Time : (Ambient)/ 0.0Kg/cm2 ~ 1.00Kg/cm2 about 45 mins

Highly Accelerated Stress Test (HAST/PCT) Chamber for Fast Reliability Testing Technical Parameters:

HAST

Model | HAST - 25 | HAST - 35 | HAST - 45 | HAST - 55 | HAST - 65 |

Internal Dimension ΦxD (mm) | 300x250 | 350x450 | 450x550 | 550x650 | 650x750 |

External Dimension ΦxD (mm) | 850x1300x900 | 900x1350x900 | 1000x1480x1000 | 1150x1650x1200 | 1300x1800x1350 |

Steam Temperature Range | Steam Temperature Range: 100℃~135℃, (143℃ is optional) |

Relative Pressure/ Absolute Pressure | Relative pressure: display values indicated on the pressure gauge Absolute pressure: pressure gauge value adds 100 kPa (The actual value in the inner box) |

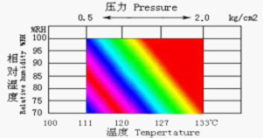

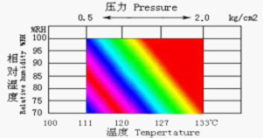

Comparison Table of Temperature, Humidity, Pressure |

|

Steam Humidity | 70~100 % R.H. steam humidity adjustable |

Steam Pressure(Absolute Pressure) | 101.3Kpa +0.0Kg/cm2 ~ 2.0Kg/cm2 ; (3.0Kg/cm2 is special standard) |

Recursive Device | Steam is forced-circulation |

Safety Protective Device | Water short storage protection, overpressure protection. (have automatic/manual water replenishing, automatically discharge pressure function ) |

Accessories | Two layers of stainless steel plate |

Equipment Capacity(L) | 17 | 43 | 87 | 155 | 250 |

Power | AC 220V(±10%), 1∮ 3 Lines ,50/60HZ; AC 380 V(±10%) ,3∮ 5 Lines,50/60HZ |

PCT

Model | PCT - 25 | PCT - 35 | PCT - 45 | PCT - 55 | PCT - 65 |

Internal Dimension Φ×D (mm) | 300×250 | 350×450 | 450×550 | 550×650 | 650×750 |

External Dimension Φ×D (mm) | 750×1200×800 | 800×1250×800 | 900×1380×900 | 1050×1550×1100 | 1200×1700×1250 |

Temperature Range of Saturated Steam (Operating temperature) | (Temperature Range of Saturated Steam:100℃~135℃) , Temperature Range: 120℃,100Kpa/ 133℃ 200 Kpa;(143℃ is special order) |

Relative Pressure/ Absolute Pressure | Relative pressure: display values indicated on the pressure gauge Absolute pressure: Value that adds 100 kPa based on the display values indicated on the pressure gauge (The actual value in the inner box) |

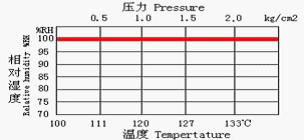

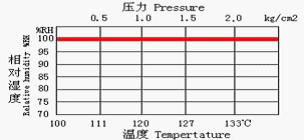

· Comparison Table of Temperature, Humidity, and Pressure of Saturated Steam |

|

Humidity of Saturated Steam | 100% RH saturation steam humidity |

Steam Pressure(Absolute Pressure) | 101.3Kpa +0.0Kg/cm2 ~ 2.0Kg/cm2 ; (3.0Kg/cm2 is special standard) |

Recursive Device | Steam Natural convection circulation |

Safety Protective Device | Water short storage protection, overpressure protection.(have automatic/manual water replenishing, automatically discharge pressure function ) |

Accessories | Two layers of stainless steel plate |

Equipment Capacity(L) | 17 | 43 | 87 | 155 | 250 |

Powder | AC 220V(±10%), 1∮ 3 Lines ,50/60HZ ; |