Product Description

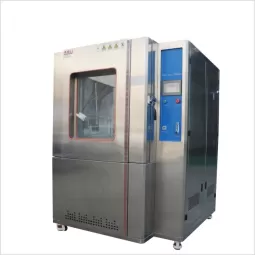

Programmable Touch Screen Control Salt Spray Fog Test Chamber is specially designed for the testing of the corrosion erosion Resistance of the products after their material surfaces have been treated with electric plating, anodizing, Spray coating, anti-rusting oil, and other anti-erosion treatments.

Salt Spray Fog Testing Chamber Features:

1. Adopt automatically or manually adding a water system, which can water itself while lack of water.

2. Precise glass spray nozzle, good uniformity, mist drops naturally, no NaCl crystallized salt

3. Double over-heat protection device and alarm when water short time to ensure user safety.

4. Digitally temperature controller, PID controlled, precision of ± 0.1ºC

5. Laboratory direct steam-heated, even heating speed, reducing the standby time.

6. Tapered Spray tower, even mist dropping

7. Saturated bucket is SUS #304, convenient for heating and humidifying, offers humidity for testing

8. Concentration of NaCl: 5%; PH of the water: 6.5-7.2 (Liquid)

Product Parameters

| Programmable Touch Screen Control Salt Spray Fog Test Chamber Technical Parameters |

| Model | SH-60 | SH-90 | SH-120 | SH-160 | SH-200 |

Internal Dimension

W*H*D (mm) | 600*450*400 | 900*600*500 | 1200*800*500 | 1600*800*500 | 2000*1000*500 |

External Dimension

W*H*D (mm) | 1100*600*1200 | 1400*950*1200 | 1900*1300*1400 | 2300*1300*1400 | 2700*1500*1500 |

| Lab Temperature | Saline test (NSS ACSS) 35±1 degree C ;Corrosion Test (CASS)50±1 degree C |

Pressure Bucket

Temperature | Saline test method (NSS ACSS) 47±1 degree C / Corrosion Test (CASS)63±1 degree C |

| Lab Capacity(L) | 110 | 270 | 500 | 800 | 1500 |

| Saline Capacity(L) | 15 | 25 | 40 | 40 | 40 |

| Saline Concentration | 5% concentration of NaCl, or for every Liter of 5% NaCl, add 0.26g CuCl2H2O |

Compressed Air

Pressure(Kgf) | 1.0~6.0 |

| Spray Volume | 1.0~2.0ml /80cm2 /h(working at least 16 hours, and take the average value) |

| Spray Form | Continuous Spraying or Programmable Spraying |

| Power | AC220V 1phase 3 lines15A |

| Weight(Kg) | 65 | 80 | 120 | 160 | 200 |

Detailed Photos

Salt Spray Testing Chamber pictures:

Customer Visiti ASLI Salt Spray Test Chamber

Certificate:

Exhibition:

Please feel free to contact me if any needs about Programmable Touch Screen Control Salt Spray Fog Test Chamber.