Ensuring Battery Safety: The Role of Explosion-Proof and Temperature Testing Chambers in Lithium-Ion Battery Testing

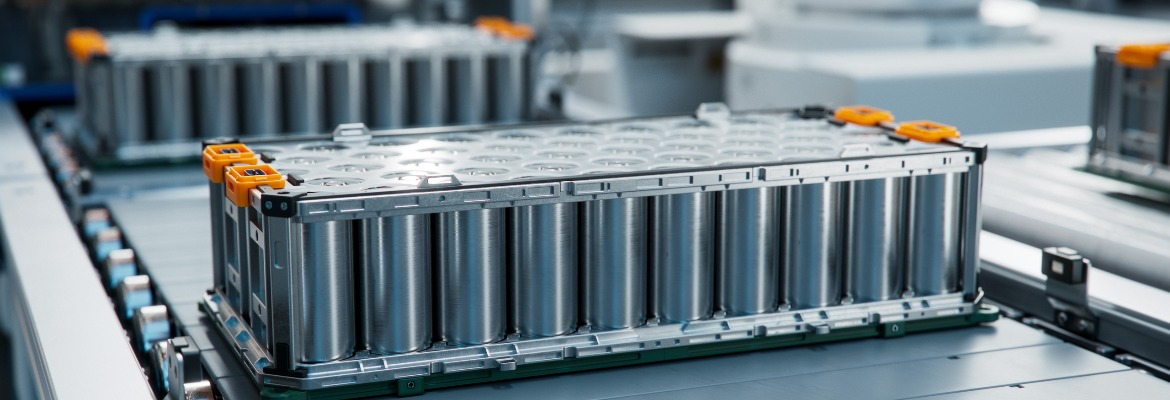

As the use of lithium-ion batteries grows in consumer electronics, electric vehicles (EVs), and wearable devices, so does the potential risk associated with their operation. Despite their many advantages, lithium-ion batteries have inherent risks, including overheating, thermal runaway, explosion, and fire. To ensure the safe use of these batteries, rigorous testing is necessary—especially under extreme conditions. This is where specialized testing equipment, such as Explosion-Proof Battery Test Chambers and Temperature-Humidity Test Chambers, plays a critical role in safeguarding both consumers and manufacturers.

Explosion-Proof Battery Test Chambers: A Core Tool for Safety Testing

An Explosion-Proof Battery Test Chamber is designed specifically to evaluate the safety and performance of batteries under extreme test conditions. These chambers simulate various scenarios such as high temperatures, overcharging, mechanical impact, and internal faults. Through these tests, engineers can assess whether a battery might explode, catch fire, or otherwise fail under certain conditions.

Key Features and Benefits of Explosion-Proof Battery Test Chambers:

Simulating Extreme Environments: These chambers are capable of replicating critical testing conditions like high temperatures, overcharging, short circuits, and deep discharge. Such testing is essential to assess how batteries behave during accidents or extreme conditions.

Advanced Safety Design: Modern explosion-proof chambers come with features like gas leak monitoring, fire suppression systems, and pressure relief valves to minimize the risk of fire or explosion during testing.

Comprehensive Testing Capabilities: In addition to basic performance testing, these chambers can also assess short-circuiting, overcharge, and over-discharge scenarios, ensuring a more thorough evaluation of a battery’s safety and reliability.

Temperature-Humidity Test Chambers: A Crucial Equipment for Environmental Testing

Along with explosion-proof chambers, Temperature-Humidity Test Chambers are vital in assessing how lithium-ion batteries perform in different climate conditions. These chambers simulate both extreme temperature and humidity levels, providing insight into how a battery behaves under challenging environmental factors. Testing battery performance under varying temperatures and humidity levels helps manufacturers understand its long-term reliability and safety in real-world conditions.

For example, our Temperature-Humidity Test Chambers offer precise control over temperature, ranging from -40°C to 150°C, and humidity levels from 20% to 98%. This ensures that engineers can simulate a wide range of environmental conditions to test the battery's resilience and stability.

Essential Battery Safety Standards and Certifications

To ensure that batteries are safe and perform well, various international safety standards and certifications have been established. Below are some critical standards that guide battery testing:

UL 2054: This standard, issued by Underwriters Laboratories (UL), focuses on the safety of batteries in consumer products. It aims to prevent battery explosions, fires, and other safety hazards during regular use and testing.

IEC 62133: Set by the International Electrotechnical Commission (IEC), this standard is crucial for the safety of portable rechargeable batteries, especially lithium-ion batteries, during use and testing.

UN38.3: This standard, established by the United Nations, provides safety requirements for the transport of lithium-ion batteries. It ensures that batteries can withstand extreme conditions during transport, including shock, vibration, and changes in temperature and altitude.

By complying with these standards, battery manufacturers can ensure that their products are safe for use, providing reliable power solutions to consumers while adhering to global regulatory requirements.

How to Choose the Right Battery Testing Equipment

Selecting the appropriate testing equipment is crucial for ensuring the safety and performance of batteries. Here are some key factors to consider when choosing battery testing equipment:

Testing Range: Ensure that the equipment can simulate the required testing conditions. Different battery applications, such as electric vehicles or portable devices, may require different test setups.

Safety: High-quality testing equipment should come equipped with advanced safety systems to prevent accidents during the testing process.

Reliability and Precision: Testing equipment should have the ability to precisely control and monitor environmental conditions to ensure accurate and repeatable results.

Compliance with Standards: Ensure that the testing equipment adheres to relevant international safety standards, minimizing any safety risks during testing.

Conclusion: The Future of Battery Safety

As battery technologies continue to evolve, Explosion-Proof Test Chambers and Temperature-Humidity Test Chambers will remain indispensable in ensuring the safety and performance of lithium-ion batteries. These testing devices not only help manufacturers meet regulatory requirements but also ensure that consumers receive reliable and safe battery-powered products. By choosing the right testing equipment and adhering to relevant safety standards, battery manufacturers can offer safer and more dependable products in an increasingly battery-dependent world.

With these thorough tests, manufacturers can improve product quality, enhance competitiveness in the market, and most importantly, ensure consumer safety.

References:

UL 2054: Underwriters Laboratories. Official UL website.

IEC 62133: International Electrotechnical Commission. Official IEC website.