Table of Contents:

Introduction

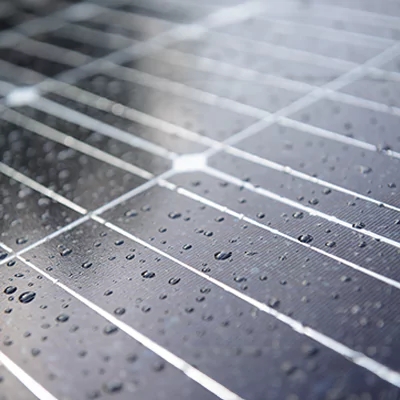

In the world of solar energy, ensuring that solar panels perform reliably under various environmental conditions is paramount. A Damp Heat Test Chamber is an essential tool used by manufacturers to simulate high humidity and temperature environments. This testing helps assess the durability, performance, and safety of solar panels over extended periods. By subjecting panels to extreme conditions, manufacturers can predict their long-term behavior and ensure they meet international quality standards.

What is a Damp Heat Test Chamber?

A Damp Heat Test Chamber is a specialized environmental testing device that simulates high temperature and high humidity conditions. It is primarily used to evaluate the performance of various products, including solar panels, under prolonged exposure to extreme conditions. The chamber controls temperature (often ranging from -40°C to 85°C) and humidity (up to 98% RH), creating a testing environment that mirrors tropical climates or harsh industrial environments.

Why is Damp Heat Testing Important for Solar Panels?

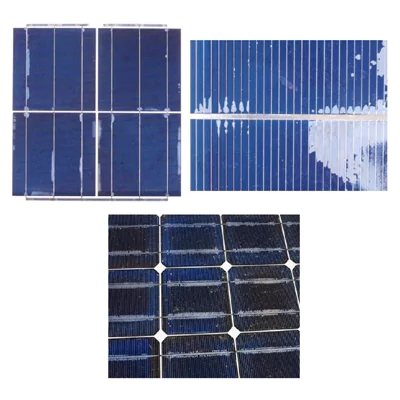

Damp Heat Testing is a crucial part of the reliability testing process for solar panels. Prolonged exposure to humidity and high temperatures can degrade materials, damage electrical components, and decrease overall efficiency. Here’s why testing is essential:

Performance Under Extreme Conditions: It tests solar panels' ability to maintain performance in hot and humid environments where energy output might degrade.

Corrosion Resistance: Panels must withstand moisture exposure without corroding their metal parts or degrading the surface materials.

Ensures Safety: High humidity and temperature can lead to electrical failures, so this testing helps ensure the safety of solar panels.

Relevant Testing Standards (IEC 61215, IEC 61730)

The importance of Damp Heat Testing is further highlighted by international testing standards such as:

IEC 61215: This standard ensures that photovoltaic (PV) modules, including solar panels, meet the required quality standards. Specifically, MQT 13 involves Damp Heat Testing to assess durability against moisture and high temperatures.

IEC 61730: This standard focuses on the safety requirements for PV modules. MST 53 outlines how solar panels should be tested for moisture resistance to prevent safety hazards such as electrical shorts or fires.

Applications of Damp Heat Test Chambers

Damp Heat Test Chambers are used in various industries where products are exposed to high humidity and temperature. However, their application is critical in the solar energy industry. Some specific applications include:

Solar Panel Testing: Ensuring that panels remain efficient, corrosion-resistant, and safe after prolonged exposure to extreme environmental conditions.

Consumer Electronics: Testing products like phones, laptops, and televisions for humidity and heat resistance.

Automotive Components: Ensuring that car parts such as batteries and electrical systems perform reliably under damp conditions.

Key Features of Damp Heat Test Chambers

When selecting a Damp Heat Test Chamber for solar panel testing, consider the following key features:

Temperature and Humidity Control: Chambers should provide precise control over temperature and humidity levels.

Uniformity: Ensure even distribution of temperature and humidity inside the chamber to avoid test discrepancies.

Energy Efficiency: Look for models that are energy efficient, ensuring lower operational costs while maintaining high performance.

Compliance with Standards: Ensure that the test chamber complies with industry standards like IEC 61215 and IEC 61730 to meet regulatory and quality requirements.

How to Choose the Right Damp Heat Test Chamber?

To select the right Damp Heat Test Chamber, manufacturers should consider:

Temperature Range: The chamber should accommodate the required temperature range for your solar panels.

Capacity: Ensure that the chamber can accommodate the size of the solar panels you need to test.

Control Systems: Opt for chambers with advanced control systems and automation features to facilitate easier testing.

Conclusion

Damp Heat Testing plays a crucial role in ensuring that solar panels can endure high temperature and humidity, two factors that can impact performance, longevity, and safety. By using the right Damp Heat Test Chamber, manufacturers can guarantee that their products meet industry standards, ensuring the long-term viability of solar panels in demanding environments.

References

IEC 61215: Crystalline Silicon Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval

IEC 61730: Photovoltaic (PV) Modules – Part 1: Requirements for Design Qualification and Part 2: Requirements for Testing

ISO 17025: General requirements for the competence of testing and calibration laboratories

"Innovation in Testing, Reliability in Results" – Asli Test Equipment Co., Ltd. – Your trusted partner in precision testing solutions for the solar industry.