IEC 62133-2017

UL 1642

UN 38.3

What types of test chambers are available?

Programmable Control Temperature Humidity Fast Change Rate Test Machines are available as standard products in a variety of sizes to suit your needs. Our environmental test chambers are often used for steady-state stability testing, basic temperature cycling, and accelerated stress testing.

Control system:

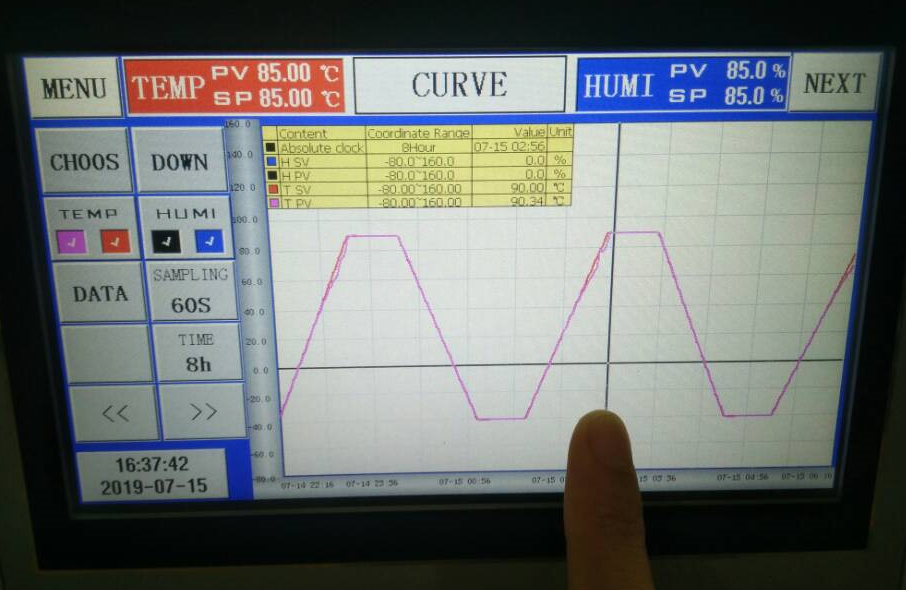

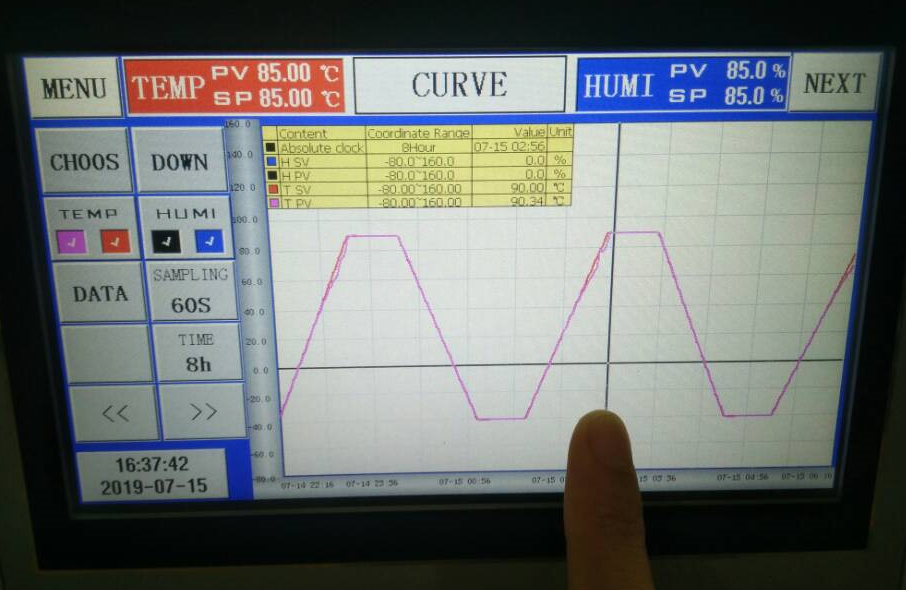

1. Imported LCD display screen, capable of displaying the measured value as well as the set value and time.

2. A fixed condition or programmable condition can be set.

3. Fixed condition setting time range: 0 - 99 H 59 MIN.

4 . Programmable mold can set 100 different programs at the same time, each program can set several segments to do cycle testing

5. Each program can have a maximum of 100 segments with different temperature settings, segment running time.59 H99M, Max..can do 999 times cycle.

6. With the power off the memory device, reply message to continue with the rest of the program.

7. The control unit has the functions of multiple segment program editing, and of quick or slope control of temperature and humidity.

8. With TIMER SIGNAL OUTPUT RELAY.

9 . Temperature sensor adopts DIN PT-100Ω

10. Adopt the BTHC system to control temperature and humidity, P.I.D. control S.S.R..

11. With the P.I.D. auto-calculate function.

12. With an alarm function when running or setting a fault.

13. 5-year memory backup device while powered off

14. With the LOCK function for the interface.

15. Recorder is optional

Technical Parameters:

Model | F-TH-80 (A~F) | F-TH-150 (A~ F) | F-TH-225 (A~F) | F-TH-408 (A~F) | F-TH-800 (A~ F) | F-TH-1000 (A~F) |

Internal Dimensions W x H x D(cm) | 40x50x40 | 50 x 60 x 50 | 60 x 75 x 50 | 80 x 85 x60 | 100x100x80 | 100x100x100 |

External Dimensions W x H x D(cm) | 120x165x115 | 130x170x125 | 140x185x130 | 165x195x155 | 185x200x175 | 190x210x185 |

Temperature range | Low temperature: A:+25°C, B:0°C, C:-20°C, D:-40°C, E: -60°C,F:-70°C High temperature:150°C (200°C ) |

Humidity range | 20%~98% R.H. ( 10%~98%R.H ) ; (5%~98%R.H is a special selection condition) |

Temperature and humidity analysis

accuracy/distribution accuracy | 0.1°C 0.1%R.H./±2.0°C ±3.0%R.H. |

Temperature and humidity

control accuracy | ±0.5°C, ±2.5%R.H. |

heating/cooling time | Temperature Range: -40~+150ºC;

Range of Fast Temperature Change:-45~+85ºC;

Max.. temperature rising/falling speed is 20ºC/min when the whole process is with linear control. |

Internal and external materials | The inner and outer boxes are made of SUS304# stainless steel plate (optional paint) |

Insulation material | High temperature resistant high high-density ethyl chloroformate foam insulation material |

Cooling system | Air-cooled/single-stage compressor (-20°C); two-stage compressor (-40°C-70°C) |

Safety protection device | No fuse switch, compressor overload protection, refrigerant high and low pressure protection, over-humidity over-temperature

protection, fuse, fault warning system, water shortage alarm protection |

Accessories | Operation hole built-in glass door (optional), recorder (optional), viewing window, 50mm test hole,

PL box light, partition, dry and wet ball gauze, casters, leveling stand |

Power supply | AC380V 50/60Hz3∮ |

Programmable Control Temperature Humidity Fast Change Rate Test Machine Features:

1. Graceful appearance, circularly shaped body, surface treated with mist strips, and plane handle with no reaction. Easy to operate, safe, and reliable.

2. Rectangular double-glassed watching window for the observation of the test production during the testing process. The window is equipped witha sweat-proof electrical heating device that can prevent water steam from condensing into droplets, and with high brightness PL fluorescent bulbs to provide light inside the box.

3. Double-layer-insulated airtight doors, able to insulate the internal temperature effectively.

4. A water supply system that is externally connectable, convenient for refilling water into the humidifying pot, and automatically recyclable.

5. The French Tecumseh brand is used for the circulation system of the compressor, capable of removing the lubricant between the condensation pipes and capillaries. The environment-protecting coolant is used for the whole series (R232, R404)

6. Imported LCD display screen, capable of displaying the measured value as well as the set value and time.

7. The control unit has the functions of multiple segment program editing, and of quick or slope control of temperature and humidity.

8. Inserted mobile pulley, convenient for movement an relocation, with strong positioning screws.

Cooling system:

1. Imported power saving full closed compressor

2. Cooling method: air cooling.

3. Imported dry filter,electrol valve.,etc freeze accessories.

4 . Air cooling type Conder, attached with a heat dissipation motor device or water cooling pipe.

5.ryogenic system adopts dual refrigeration loop, fast cooling.

6.Expansion system: capillary capacity control refrigeration system.

Machine accuracy:

1.Tempearature Analytic accuraty:0.1ºC Humidity Analytic accuraty: 0.1R.H.

2.Temperature Control accuracy : ± 0.5 Deg C Humidity Control accuracy : ± 2.5% R.H.

3.Tempeartuer Distribution uniformity:± 2.0 Deg C Humidity Distribution uniformity: ± 3.0R.H.

P.S.: All the above test index tested 2 hours later after the machine running stable, under the conditioning no live load and non linear control.

Exhibition:

Welcome our new and regular customers visit our factory, and any inquiries about Programmable Control Temperature Humidity Fast Change Rate Test Machine, please feel free to contact us !